Company profile

Motta & Rossi was founded in 1978 and today it is one of the leading companies in the metal sector.

Motta & Rossi was founded in 1978 and today it is one of the leading companies in the metal sector.

With over thirty years of experience, the company has reached a high quality level and is constantly improving to be always ready to positively react to the various needs of the market.

In 2003 the factory premises doubled thanks to the new plant in the industrial area with direct access to the main road.

To the initial 3.000 covered square meters of the first plant, currently used for the painting activity, another 6.000 covered square meters were added with the new plant mainly used for metal working.

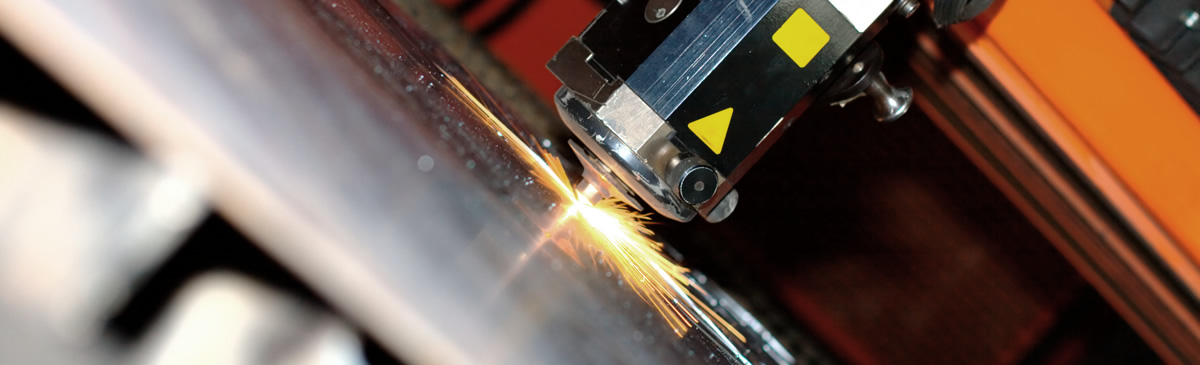

Motta & Rossi has been one of the first companies in Italy to use the laser technology for cutting tubes, which remains a safe and reliable working method for metal workers.

Thanks to a really impressive variety of special machines and to a definitely highly qualified and well trained team of experts, Motta & Rossi can respond to the most complex market needs with competence and flexibility in working metal.

The whole working process is fully traceable: from the initial cutting phase to the packaged finished product in a verticalized production sequence including: bending, welding, pressing, tapering, assembling, epoxy painting, welding.

Every single product is inspected by experts in all its technical details, and this system is not only important from a quality point of view, which is confirmed by the ISO certificate 9001, but also evidence of great professionalism.

Principles and quality

All working activities are inspired by the basic principles of the company, which have also become the focus:

- Flexibility and technical competence. Always meeting the customer’s needs looking for solutions to any specific request with care and professionalism for top quality results.

- Production. Execute every single phase of the production cycle with care and attention, from cutting to packaging.

- Quality. The regularity of the company organization is certified by ISO 9001. Quality in terms of production inspection to assure that every single piece is perfect in all its parts thanks to the supervision of specialized personnel.

- Technology. A wide machine equipment, constantly updated to the most advanced technologies and a really modern IT service that provides complete traceability and an immediate control on the origin of every single production lot.

- Environment. Committed to environment and to energy saving by means of the installation of photovoltaic panels resulting in a consumption and emission reduction by over 25%.